B.W.T...Link

by the students, for the students

How To Fix Binding

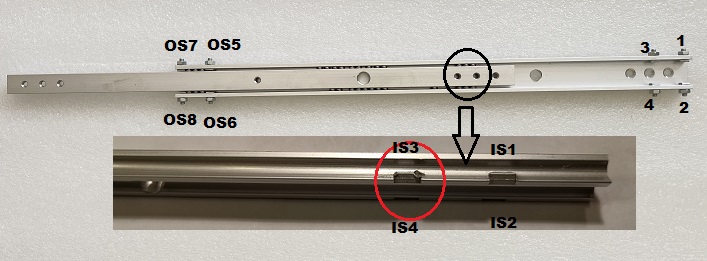

One of the normal causes of binding is from repeated extension and retraction of slides at a high speed. This operation over time wears down the end stop (see image below), making it difficult for the ball bearings to roll smoothly as intended.

Fortunately, BWTLink's slide is the one and ONLY one that can be easily modified to avoid binding caused from high speed usage. Our new versions,

BL-300A-2M, BL-300B-2M, BL-300C-2M, BL-350C.-2M, BL-400A-2M, and BL-400B-2M have resolved this binding issue!

This article provides a detailed guide for teams who purchased our first version (BL-300-2M) of slides to fix binding on your own.

Instructions:

BWTLink Series Drawer Slide Disassembly/Reassembly Tutorial